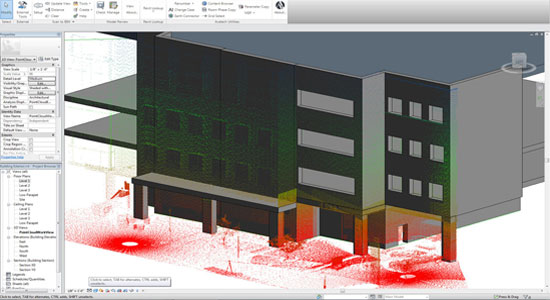

The recently released IMAGINiTs Scan to BIM 2014.1 software for renovation and retro?t projects, and which is available on a rental basis builds upon the Autodesk Revit platform to offer additional point cloud functionality and modeling data that can be relied and validated. This latest version of the Scan to BIM software aids users in creating 3D building information model (BIM) in Autodesk’s Revit building design software from point cloud data.

With Scan to BIM users can view point clouds in Revit more precisely and create as well as validate any model from a point cloud with automated recognition and placement of architectural elements like walls and columns, as well as MEP elements like pipes, conduits, ducts, etc. Besides, it is compatible with Revit 2012, 2013 or 2014. Users can also rent Scan to BIM on a quarterly or yearly basis for any specific project.

Capable of creating native Revit geometry from a point cloud and analyzing the differences between point cloud and the model geometry, Scan to BIM includes the following features-

- Scan to BIM provides with tools to aid with creation of Revit elements that include: Walls (straight or arc), Columns (rectangular or round), Embedded Curtain Walls, Pipe, Conduit and Duct (rectangular or round), and Levels. Construction geometry to support other element types. Clean topography extraction.

- Helps interference or clearance detection for geometry vs. point cloud

- Available with workflow-based tools that help setting up and working on model with the point cloud

- Viewing enhancements to create useful views quickly to step through the project and options to toggle point cloud visibility

- Align as well as extend the prevailing geometry to match the point cloud

- Measuring points within the scan to find correct dimensions promptly

- By comparing the Revit elements against the point cloud user can visualize the accuracy

- The ability to export and import data in a format that can be understood by electronic surveying equipment, so that users can read in survey data for as-built conditions, as well as exporting design data for field verification

- Supporting floating network licenses

~~~~~~~~~~~~~~~~~

Published by

Tuhin Maity

www.bimoutsourcing.com

~~~~~~~~~~~~~~~~~~