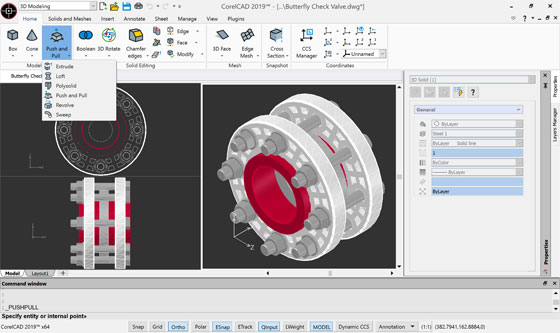

CorelCAD 2019 is launched with some extra 3D modeling tools and 3D printing capabilities along with supplementary STL support. The 3D modeling feature in CorelCAD becomes superior with the inclusion of Push and Pull editing and other tools for developing more advanced 3D solids.

CorelCAD 2019 also provides support for STL that facilitates 3D access to 3D printing files along with content accessible from sites like SketchFab and Shapeways.

Given below, the details of new features :-

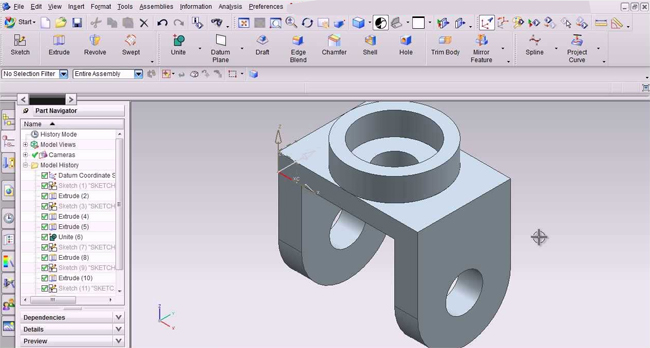

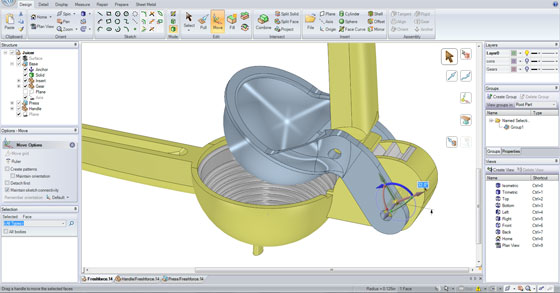

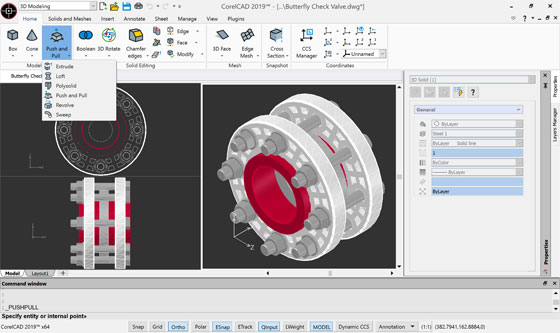

1. New 3D modeling: With the inclusion of PolySolid, it becomes easier to draw 3D objects in the shape of polygonal walls. By applying Push and Pull tools, the users get the ability to include depth with extrusion. The new version also contains ChamferEdges for beveling as well as new face and loop options. CorelCAD provides support for helix to generate 3D models around a cylindrical shape and support for 3D primitives to be included and edited with Boolean operations.

2. Greater 2D drafting tools: CorelCAD provides extra support for CustomBlocks, a tool having similarity with AutoCAD. With this feature, the users can develop and reuse blocks. Symbols are defined with rules and constraints so that the users will be able to set them in drawings and resize, rotate when required.

3. Layer Palette: CorelCAD contains a new Layers Manager to substitute an earlier application for layers. It’s considerably simplified as a palette that can be put away, docked, and accessible directly within the UI. It also contains a new MergeLayer feature.

4. .STL file import: Import support for stereolithography (.STL) files to deal with ready-made 3D designs or insert contained 3D solid objects into a new design. Besides, get support for 3D printing or output associated with .STL export.

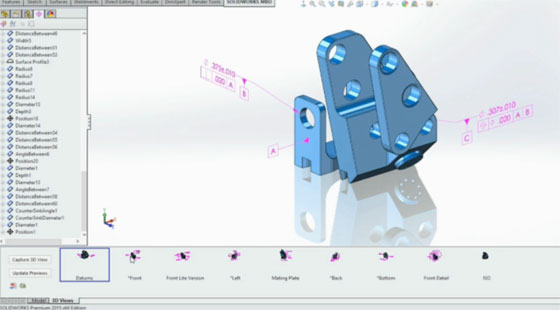

5. Improved selection tools: With CorelCAD 2019, it is possible to instantly click and cycle through entities in complex drawings and locate objects which are unseen under other objects. Preview and Selection Highlighting features are also included. Colored highlighting facilitates the users to distinguish selected and hovered-over elements.

6. Improved View options: New navigation features provide support to 3D mice and the users can view designs from several vantage points with RollView.

7. Improved File format support: The ODA DWG is upgraded to follow AutoCAD with full, native format support.

CorelCAD 2019 is accessible in English, German, Spanish, French, Italian, Brazilian-Portuguese, Czech, Polish, Russian, Turkish, Simplified Chinese, Traditional Chinese, Japanese, and Korean.

To get more details, click on the following link www.coreldraw.com

~~~~~~~~~~~~~~~~~~~~~~~~

Published By

Rajib Dey

www.bimoutsourcing.com

~~~~~~~~~~~~~~~~~~~~~~~~

CorelCAD 2019 also provides support for STL that facilitates 3D access to 3D printing files along with content accessible from sites like SketchFab and Shapeways.

Given below, the details of new features :-

1. New 3D modeling: With the inclusion of PolySolid, it becomes easier to draw 3D objects in the shape of polygonal walls. By applying Push and Pull tools, the users get the ability to include depth with extrusion. The new version also contains ChamferEdges for beveling as well as new face and loop options. CorelCAD provides support for helix to generate 3D models around a cylindrical shape and support for 3D primitives to be included and edited with Boolean operations.

2. Greater 2D drafting tools: CorelCAD provides extra support for CustomBlocks, a tool having similarity with AutoCAD. With this feature, the users can develop and reuse blocks. Symbols are defined with rules and constraints so that the users will be able to set them in drawings and resize, rotate when required.

3. Layer Palette: CorelCAD contains a new Layers Manager to substitute an earlier application for layers. It’s considerably simplified as a palette that can be put away, docked, and accessible directly within the UI. It also contains a new MergeLayer feature.

4. .STL file import: Import support for stereolithography (.STL) files to deal with ready-made 3D designs or insert contained 3D solid objects into a new design. Besides, get support for 3D printing or output associated with .STL export.

5. Improved selection tools: With CorelCAD 2019, it is possible to instantly click and cycle through entities in complex drawings and locate objects which are unseen under other objects. Preview and Selection Highlighting features are also included. Colored highlighting facilitates the users to distinguish selected and hovered-over elements.

6. Improved View options: New navigation features provide support to 3D mice and the users can view designs from several vantage points with RollView.

7. Improved File format support: The ODA DWG is upgraded to follow AutoCAD with full, native format support.

CorelCAD 2019 is accessible in English, German, Spanish, French, Italian, Brazilian-Portuguese, Czech, Polish, Russian, Turkish, Simplified Chinese, Traditional Chinese, Japanese, and Korean.

To get more details, click on the following link www.coreldraw.com

~~~~~~~~~~~~~~~~~~~~~~~~

Published By

Rajib Dey

www.bimoutsourcing.com

~~~~~~~~~~~~~~~~~~~~~~~~